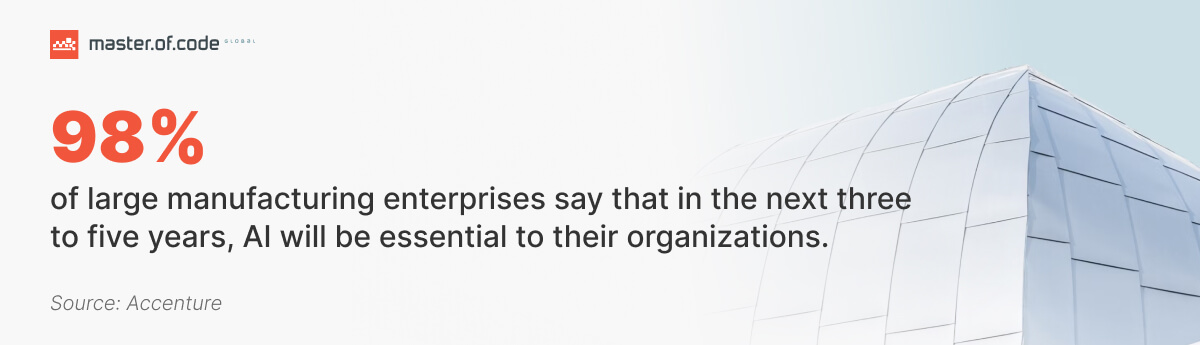

Nowadays Natural Language Processing is emerging as a transformative force. It is revolutionizing the manufacturing sector day by day, not leaving a chance for companies to escape.

In essence, this branch of artificial intelligence enables computers to understand, interpret, and generate human language. No doubt, it is finding an increasing number of applications on the factory floor. From predictive maintenance and resource optimization to the creation of fully connected smart factories — these all are results of timely and effective technology integration.

The NLP market’s exponential growth underscores its significance and adoption rate across various industries. And it seems that industrial production is leading the charge. Moreover, the market itself is predicted to be almost 14 times larger in 2025.

We can state that this is just a matter of time for factories to embark on a journey to full digitalization. But how to make this shift as smooth and painless as possible? Read this article to discover more about the multifaceted role of NLP in manufacturing. Let’s explore in detail how the technology enhances efficiency, improves decision-making, and paves the way for a more intelligent and automated future. We will also break down the main challenges and opportunities for implementation, so that you could easily integrate these best practices into your strategy and avoid common pitfalls.

Table of Contents

Key Applications of NLP in Manufacturing

Predictive Maintenance

Natural Language Processing algorithms delve into maintenance logs, sensor data, and even technician notes. It’s done to uncover patterns indicative of impending equipment failures. Workers can proactively schedule repairs, minimize downtime, and optimize operational costs. They do it by detecting anomalies and predicting maintenance needs. 47% of global manufacturers use NLP algorithms for this purpose to reduce operational costs.

Quality Control

NLP-powered systems analyze feedback, product reviews, and social media chatter. It helps to identify potential quality issues. This real-time monitoring enables rapid response to production line problems. At the same time, it’s ensuring consistent product quality and customer satisfaction.

Supply Chain Optimization

Language processing facilitates seamless communication. It’s done by interpreting native queries and providing automated responses. This accelerates information exchange, simplifies order processing, and enables faster decision-making. Additionally, NLP can extract insights from unstructured data like shipping documents and contracts. Generative AI in supply chain makes planning easier and more cost-effective.

Technological Shift and Customization

Manufacturing processes can be innovatively revamped and tailored. This could involve creating domain-specific chatbots for employees. The same relates to automating routine tasks, or developing personalized training modules. Such tailored solutions use the power of NLP to optimize workflows and improve overall efficiency.

Real-time Language Translation

In global production operations, language barriers can hinder communication and collaboration. Natural Language Processing enables translation of text and speech on the go. This fosters better understanding between teams across different regions and cultures. International companies can successfully implement NLP to improve communication efficiency, reduce errors, and promote a more cohesive workforce.

Read also: Why Use Natural Language Processing

Innovative Use Cases of NLP in Manufacturing

Additive Manufacturing

AI is instrumental in revolutionizing 3D printing processes. This industry is about to reach a value of USD 69.3 billion by 2030 at a CAGR of 21.6% between 2023 and 2030. NLP algorithms can analyze and interpret design specifications and material properties. They can also process parameters described in natural language.

Long story short, this approach streamlines the transition from design to production. It also helps minimize errors and ensure precise fabrication. Moreover, AI-powered optimization algorithms can recommend ideal print settings and material choices. At the end of the day, manufacturers can enhance product quality and reduce waste.

Generative Product Development

By automating design processes and optimizing product features, AI-driven systems create innovative solutions faster than traditional methods. NLP enhances collaboration by interpreting and processing complex data, enabling easy connection between human designers and AI tools. This synergy accelerates prototyping, reduces costs, and drives unprecedented innovation, making it a cornerstone of modern manufacturing.

Digital Twins

These models create virtual replicas of physical manufacturing systems. They mimic behavior and performance in real time. The digital counterparts are fed with sensor data, maintenance logs, and operational information. It is analyzed using NLP algorithms to detect anomalies, predict failures, and optimize maintenance schedules.

Digital twins enable proactive decision-making, reducing downtime and ensuring continuous production. Additionally, they facilitate virtual testing and experimentation. This way, manufacturers get an opportunity to evaluate changes and improvements in a risk-free environment.

Benefits of Natural Language Processing for the Industry

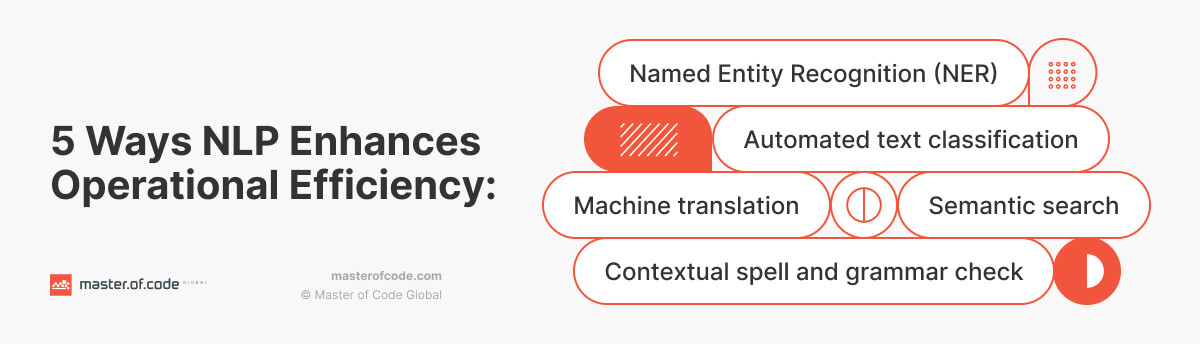

More than 50 companies that outsource their Conversational AI and NLP chatbot services will continue to do so by 2029. Natural Language Processing is transforming industries by unlocking the potential of human language data. Here’s how it’s boosting efficiency, worker engagement, and client service:

Efficiency and Productivity. Language processing streamlines operations by automating tasks that previously required manual input. For instance, NLP-powered systems can extract information from unstructured documents, classify customer feedback, and even generate reports. It significantly reduces the time and resources needed for these tasks. Speech processing also enhances data retrieval. People can quickly find relevant information within vast databases or documents. This ultimately leads to faster decision-making and improved productivity.

Employee Engagement and Training. NLP-powered tools can create interactive training materials, making learning more accessible and effective. Chatbots and virtual assistants can also provide valuable and real-time assistance to workers. They are answering questions, offering guidance, and troubleshooting problems on the spot. This not only improves workforce efficiency but also boosts job satisfaction as employees feel empowered.

Enhanced Customer Service. NLP in manufacturing is reshaping user experience. It automates responses to requests, resolving issues more efficiently, and providing personalized support. Generative AI chatbots can handle routine questions and come up with native answers, while human agents focus on complex interactions. Language processing powered sentiment analysis can gauge contentment levels. It allows for proactive interventions and personalization. This leads to faster response times, improved experiences, and increased loyalty.

Digital Transformation with NLP

Language computing is a linchpin within the manufacturing industry. It acts as a bridge between humans and machines, enabling seamless interaction and unlocking valuable insights from unstructured data. In the realm of digital transformation, NLP plays a pivotal role in several key areas:

- Data-Driven Decision Making. Generative AI in manufacturing produces massive amounts of information. It includes a range from sensor readings to maintenance reports. NLP can extract meaningful pieces from this unstructured data and transform it into actionable insights. This empowers decision-makers with a clearer understanding of operations. They can identify bottlenecks, optimize processes, and improve overall efficiency.

- Human-Machine Collaboration. Virtual assistants facilitate seamless communication between people and digital tools. The chatbots can answer queries, provide instructions, and even troubleshoot problems. It enhances productivity and reduces the need for human intervention in routine tasks. This not only frees up workers for more strategic activities but also fosters a more collaborative and efficient environment.

- Predictive Analytics and Maintenance. NLP, combined with machine learning algorithms, can analyze historical data. This way, it becomes much easier to predict potential equipment failures or maintenance needs. Such a proactive approach minimizes downtime, reduces end costs, and ensures smooth production flow. Text analysis enables manufacturers to anticipate and prevent disruptions. This is done by identifying patterns and anomalies in language data. As a result, factories can improve operational resilience.

- Customer-Centricity. NLP in manufacturing provides automated responses to inquiries. It resolves issues timely and offers personalized recommendations. Chatbots can perfectly handle routine interactions. Sentiment analysis tools gauge satisfaction levels, allowing for proactive interventions and targeted improvements. By the way, 59% of consumers want businesses to use their data to create personalized experiences.

Digital transformation service providers integrate NLP to deliver these benefits that address specific industry challenges. They use text processing algorithms for data extraction, sentiment analysis, machine translation, and chatbot development. By integrating the technology into existing systems and processes, these solutions give the ability to harness the power of language data. Also, they assist in streamlining operations, enhancing customer journey, and ultimately driving digital transformation across the value chain.

Curious about how machine learning is revolutionizing manufacturing? Discover more in our detailed article on Machine Learning in Manufacturing and learn how AI is shaping the future of smart factories.

Challenges in Implementation

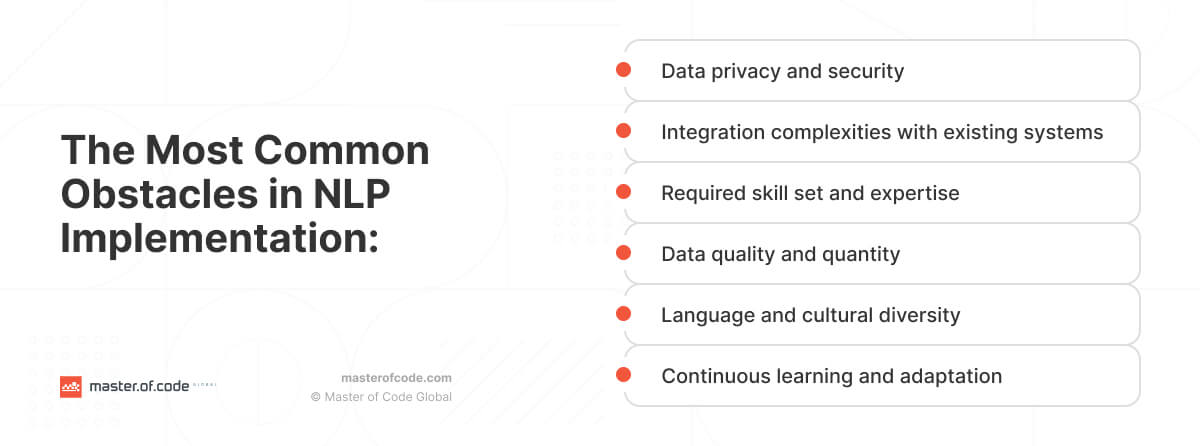

While the potential benefits of NLP in manufacturing are undeniable, several obstacles can arise during its integration. Addressing these challenges proactively is crucial for successful implementation and realizing the full value of Natural Language Processing services. So, how to avoid common pitfalls and partner with the right service provider?

Data Privacy and Security

Manufacturing data often contains sensitive information about processes, equipment, and even customer orders. Robust data governance policies, encryption protocols, and access controls are essential to safeguard information from unauthorized access or breaches. Partnering with AI development firms experienced in data security can help implement these measures effectively.

Integration Complexities

Implementing NLP into existing systems and processes can be a difficult undertaking. Legacy systems might not be compatible with modern technologies, requiring custom integrations and potential data format conversions. To overcome this, it’s crucial to work with artificial intelligence experts who understand both the production domain and the intricacies of integrating AI solutions seamlessly into existing infrastructures.

Skill Set Requirements

Implementing NLP in manufacturing often demands specialized expertise. Data scientists, AI engineers, and domain experts are needed to develop, train, and deploy effective models. For many factories, building an in-house team with these skills can be costly and time-consuming. Partnering with experienced AI development firms can provide access to the necessary expertise without the need for extensive internal hiring.

Change Management

Introducing new technologies can be met with resistance from employees who are accustomed to traditional ways of working. Clear communication, comprehensive training programs, and demonstrating the benefits of NLP through pilot projects can help address these concerns and ensure smooth adoption.

Cost and Return on Investment (ROI)

The initial funding in text analysis can be substantial, including software licenses, hardware upgrades, and personnel training. It’s essential to have a clear understanding of the potential ROI and develop a phased implementation plan to manage costs effectively. Our ROI Calculator will help you wisely handle your budget.

By proactively addressing these challenges and collaborating with a trustworthy artificial intelligence development company like Master of Code Global, manufacturers can successfully navigate the implementation of NLP solutions. This way, they will painlessly unlock their transformative potential and reap the rewards of elevated efficiency, productivity, and decision-making.

Case Studies and Industry Insights

Real-world examples demonstrate the tangible impact of NLP in manufacturing:

Siemens. The industrial giant utilizes text processing to analyze sensor data and maintenance logs, enabling predictive repair of its machinery. This proactive approach reduces downtime, optimizes schedules, and ensures consistent production output.

General Electric (GE). GE Aviation employs human language analyzing technology to process vast amounts of technical documentation and maintenance records. NLP-powered tools help engineers quickly identify relevant information, troubleshoot issues, and accelerate repairs, leading to significant time and cost savings.

Bosch. The automotive supplier uses language computing to analyze customer feedback and social media sentiment related to its products. This real-time monitoring helps detect emerging quality issues or trends, allowing Bosch to take measures in advance.

BMW. The luxury car manufacturer employs NLP in its production line to analyze data from various sensors and quality control checkpoints. This enables early detection of defects and anomalies, ensuring that only flawless vehicles leave the factory. The approach has proven to safeguard brand reputation and client loyalty.

Airbus. The aerospace company uses Natural Language Processing for real-time translation of technical documents and communication between multilingual teams. This improves collaboration, reduces errors, and accelerates project timelines in the highly complex aerospace production environment.

Industry Insights:

Market leaders are optimistic about the future potential of NLP in manufacturing. They believe that it will continue to evolve, becoming more sophisticated and capable of addressing even more complex challenges. Some key insights from MOCG experts include:

- Achieving autonomous manufacturing will heavily rely on NLP, allowing machines to learn and adapt independently, thus boosting efficiency and minimizing human intervention.

- Enhancing the capabilities of industrial robots, text handling will enable them to comprehend and respond to natural language commands, making operations more versatile and user-friendly.

- Empowering workers on the factory floor, NLP will provide real-time information and decision support tools, thereby enhancing productivity and job satisfaction.

- Facilitating easy connection and collaboration across the entire supply chain, speech processing will improve transparency and responsiveness from suppliers to customers.

- The evolution of language engineering technologies will pave the way for innovative applications and NLP use cases in manufacturing, solidifying its role as a cornerstone of Industry 4.0.

Conclusion

Natural Language Processing is revolutionizing the manufacturing sector, ushering in a new era of efficiency, innovation, and data-driven decision-making. By harnessing the power of language, NLP is transforming how employees operate, collaborate, and interact with their systems and customers.

From predictive maintenance to quality control, supply chain optimization, and real-time translation, text processing applications are wide-ranging and impactful. Language computing is also proving to be a key enabler of digital transformation, fostering a smarter and more connected manufacturing environment.

As the technology continues to evolve, we can expect even more innovative and transformative applications of NLP in the future. The benefits are clear: improved productivity, reduced costs, enhanced quality control, and a more agile and responsive production ecosystem. For manufacturers seeking to remain competitive and drive innovation, embracing human language processing technology is not just an option—it’s a strategic imperative.

Ready to build your own Conversational AI solution? Let’s chat!