From enhancing product designs and improving quality control to optimizing inventory levels with predictive maintenance, Generative AI in manufacturing is changing the industry. Take, for instance, the remarkable Airbus experience, exemplifying how the company designs more comfortable planes.

In our article, we’ll explore the diverse use cases and the benefits that Generative AI brings to manufacturing practices. Discover how industry giants like Autodesk, Ford, and the innovative AWS Supply Chain are leveraging this cutting-edge technology.

Table of Contents

Impact of Generative AI on the Manufacturing

Did you know that the projected value of the worldwide Generative AI in manufacturing market is estimated to reach approximately USD 6,398.8 million by 2032? This powerful technology is rapidly transforming the manufacturing industry. This growth is streamlined by the benefits of Generative AI for business, such as enhanced product design, reduced costs, increased employee productivity and not only these.

Early adopters of Generative AI in manufacturing are poised to gain a significant competitive advantage. However, there are companies whose profits have suffered significant damage due to supply chain disruptions. Estimates suggest that companies will lose 45% of their average annual earnings over the next ten years. Besides, companies are struggling to find workers, and more than half (54%) of manufacturers are facing labor shortages.

The rapid growth of Generative AI in manufacturing signifies its transformative potential. However, some challenges continue to impact the industry, highlighting the need for continued innovation and adaptation.

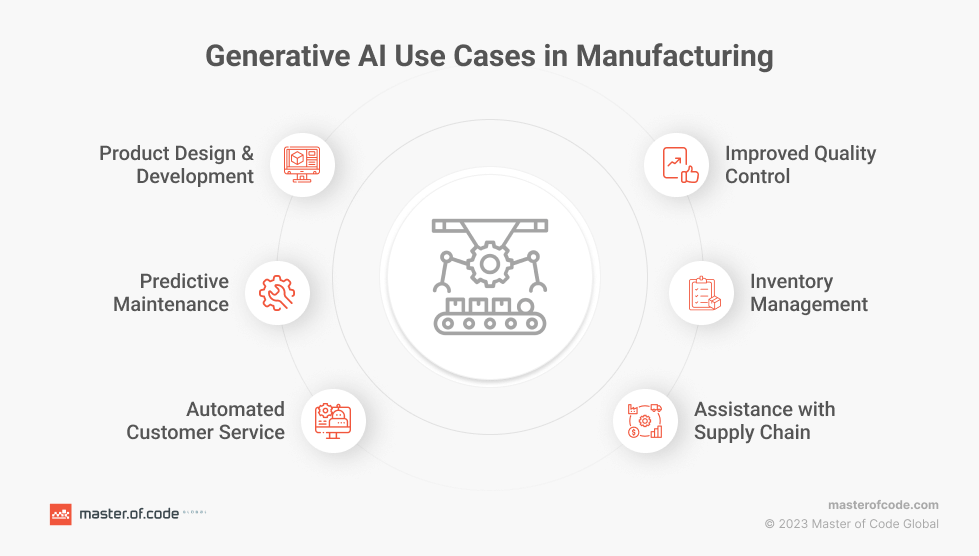

Generative AI Use Cases in Manufacturing

This prominent technology offers innovative solutions to a wide range of challenges. From design and optimization to production and quality control. So let’s discover some Generative AI use cases in the industry.

Product Design & Development

Manufacturers can apply AI to generate and test many design ideas. This use case shows how new technology helps to create better products faster.

Generative AI in manufacturing assists in exploring design options, reducing costs and time. One such example is Autodesk, which helps Airbus in creating more efficient and comfortable jetliners.

Bastian Schaefer is the Innovation Manager at Airbus, the aircraft manufacturer. He was part of the team that developed the Airbus Concept Plane, envisioning the jetliner of 2050. His main ideas were based on how passengers will travel in the future.

For instance, customers will receive tailored flight experiences according to their preferred activities. Moreover, flights will be more eco-friendly. Engineers will design future aircraft to be significantly lighter, consume less fuel, and have a reduced environmental impact.

The team chose a key piece of the aircraft to apply new technologies they’d proposed. It was the partition that separated the passenger compartment from the galley in the Airbus A320. So it will:

- be much lighter than the current partition, to reduce the weight of the plane,

- be strong enough to anchor two jump seats for flight attendants,

- have an opening for wide items to move in and out of the cabin,

- be no more than an inch thick,

- be attached to the airframe in just four places.

Predictive Maintenance

With machine learning algorithms in place, manufacturers can foresee equipment issues and maintain them proactively. Employees can train these algorithms on machine-generated data like temperature, vibration, and sound.

Day by day, the models get better at handling this data. They can predict possible breakdowns, allowing for early maintenance and less downtime. Partnering with a machine learning development firm can enhance predictive maintenance, a top-notch approach to finding and fixing possible equipment problems. Deloitte states that it can boost productivity by 25%, reduce breakdowns by 70%, and cut maintenance costs by 25%.

Automated Customer Service

For sure, customer service automation is a valuable use case for any industry. The company exists because there are clients who choose its products or services.

Gen AI helps automate customer service tasks, such as answering inquiries, giving information, and addressing common issues. By using NLP and ML, this technology can understand consumer queries and provide timely and accurate responses.

To use these abilities, companies could consider Generative AI chatbot adoption. These models can help to change dialogues, making the bot’s interactions more engaging and personalized for users. It will improve customer experience and enhance communication between the manufacturer and the client.

Improved Quality Control

This cutting-edge technology can improve quality control by identifying defects and anomalies in products. This can help manufacturers to reduce waste and improve product quality.

An example of this could be an automobile manufacturing plant. Generative AI can spot any production defects in vehicle parts, lowering the number of faulty components.

One of the biggest companies, Ford Motor, currently focuses on using AI and machine learning. The company applies these technologies in various aspects, ranging from connected car solutions to the development of self-driving vehicles.

Ford also uses AI for automating quality assurance. Artificial Intelligence can identify wrinkles in car seats, and neural networks help Ford in managing inventory and resources within the supply chain.

The program has the potential to raise quality control procedures in manufacturing. By studying past product images, Gen AI can predict potential defects in new items. This approach can notably minimize expenses and waste linked to faulty products.

Inventory Management

Generative AI can simulate different production situations and optimize inventory levels. It uses past customer data to forecast demand. These predictions help to make more accurate production schedules and keep the right amount of inventory on hand. Simulation of such situations as changes in demand and supply chain factors helps make proactive decisions, cutting unnecessary costs from overproduction or inventory shortages.

An example could be a manufacturing company using Generative AI models to predict client demand for a specific product. Having analyzed historical data and market trends, the AI recommends optimal production levels and inventory quantities. So the company could meet demand without excess inventory or stockouts. This leads to improved resource allocation and cost savings.

Assistance with Supply Chain

Generative AI for manufacturing hones the supply chain by acting as a highly intelligent assistant. This technology aids in tracking inventory and managing logistics in real-time. It’s like having a smart assistant at your company to help with the supply chain. Using advanced algorithms, it can spot supply chain issues, manage inventory, and streamline procurement.

Generative AI in the supply chain enhances its visibility and agility. Such an approach leads to improved management and increased operational efficiency.

The AWS Supply Chain application helps businesses in boosting transparency, leading to:

- more informed decisions,

- reduced risks,

- saved expenses,

- optimized customer experiences.

AWS Supply Chain helps businesses to make their logistics more resilient. It provides combined data, machine learning-based insights, suggested actions, and collaborative features.

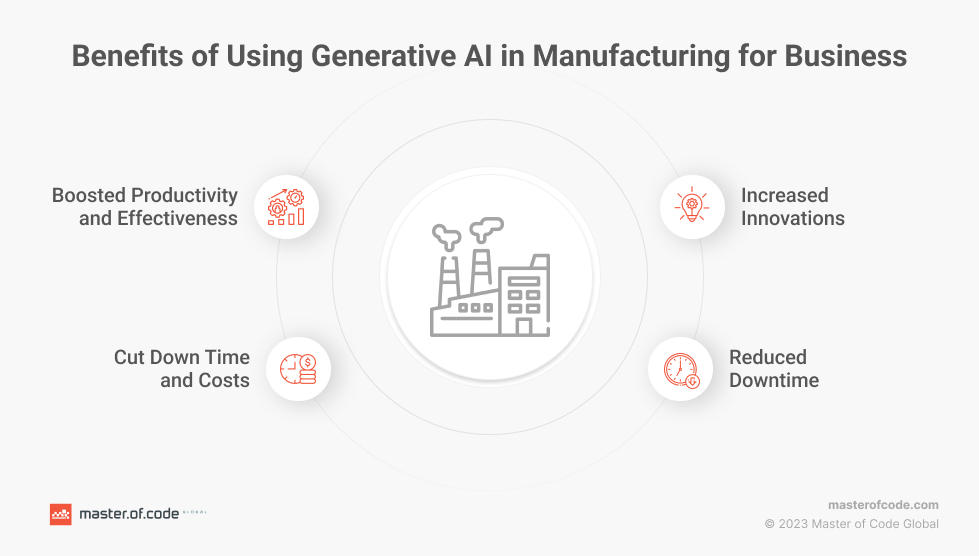

Benefits of Using Generative AI in Manufacturing for Business

Still thinking about whether you need to implement new technology? It’s time to look at the benefits it could bring to your business.

If you’re looking to apply the latest Gen AI models or customized services for your company’s unique needs, our team can assist you. The Master of Code Global has the necessary expertise to provide a full range of Generative AI services. Our engineers build and use custom language models with advanced technologies like GPT, DALL-E2, PaLM2, and more. Start your innovation journey by contacting us for a consultation.

First of all, let’s dive deeper and discover the benefits your company can reap from deploying AI-based software.

Boosted Productivity and Effectiveness

Generative AI boosts productivity and effectiveness by quickly exploring a vast array of possibilities. Businesses can design products that are more innovative, functional, and efficient.

Integrating AI into your company can help to reduce human errors. Such tools automate tasks that are prone to errors, like data entry and financial calculations. Likewise, you’ll see improved quality of products and services by identifying and correcting defects early on.

Cut Down Time and Costs

Generative AI for manufacturing can predict machine failures and reduce defects. This way, cut significant expenses on repairing or replacement.

Software can analyze machine data and identify patterns that may indicate a potential failure. This allows businesses to schedule maintenance before a machine fails, avoiding costly downtime. At the end of the day, companies reduce waste and focus on improving product quality and production consistency.

Increased Innovations

Gen AI can help manufacturers speed up their innovation cycles by simplifying the process of testing new ideas and bringing new products to market faster. Businesses can use Generative AI systems to create unparalleled designs, identify new materials, and optimize processes with out-of-the-box approaches.

Reduced Downtime

Reduced downtime is a major benefit of predictive maintenance powered by Generative AI for businesses. Unplanned downtime can be costly and disruptive. As a result, it leads to lost revenue, production delays, and client dissatisfaction.

As such models can accurately predict maintenance, they help manufacturers avoid problems and losses by identifying potential equipment failures before they occur.

To Sum Up

The presence of Generative AI in the manufacturing industry is rapidly revolutionizing the sector, bringing a lot of benefits. Enterprises are actively using this promising technology, showcasing its transformative potential in different ways. However, amidst this growth, companies continue to face challenges, emphasizing the necessity for ongoing innovation and adaptation.

Master of Code Global offers expert guidance and consultation on a wide range of LLMs and general AI models. Our skilled team focuses on delivering exceptional customer experience for the end users of the business. We will get you covered – just fill in the contact form.

Don’t miss out on the opportunity to see how Generative AI can boost your company’s efficiency.